Laboratóriumi nyomásreaktor vákuummal és nyomásfokozó szivattyúval

- HXCHEM

- Kína

- 45 nappal a fizetés után

- 40 szett/hó

Részletek

Laboratóriumi nyomásreaktor vákuummal és nyomásfokozó szivattyúval

Kevert nyomású reaktor

Bevezetés

Labor nyomású reaktor vákuummal; Laboratóriumi nyomásreaktor nyomásfokozó szivattyúval; Csavaros zárónyomású reaktorok; Labor nyomásreakciós rendszer; Labor mágneses nyomású reaktorok

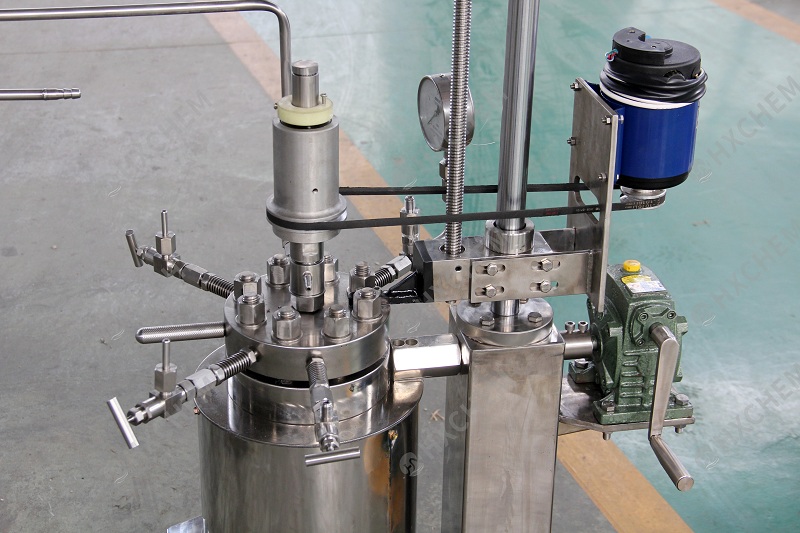

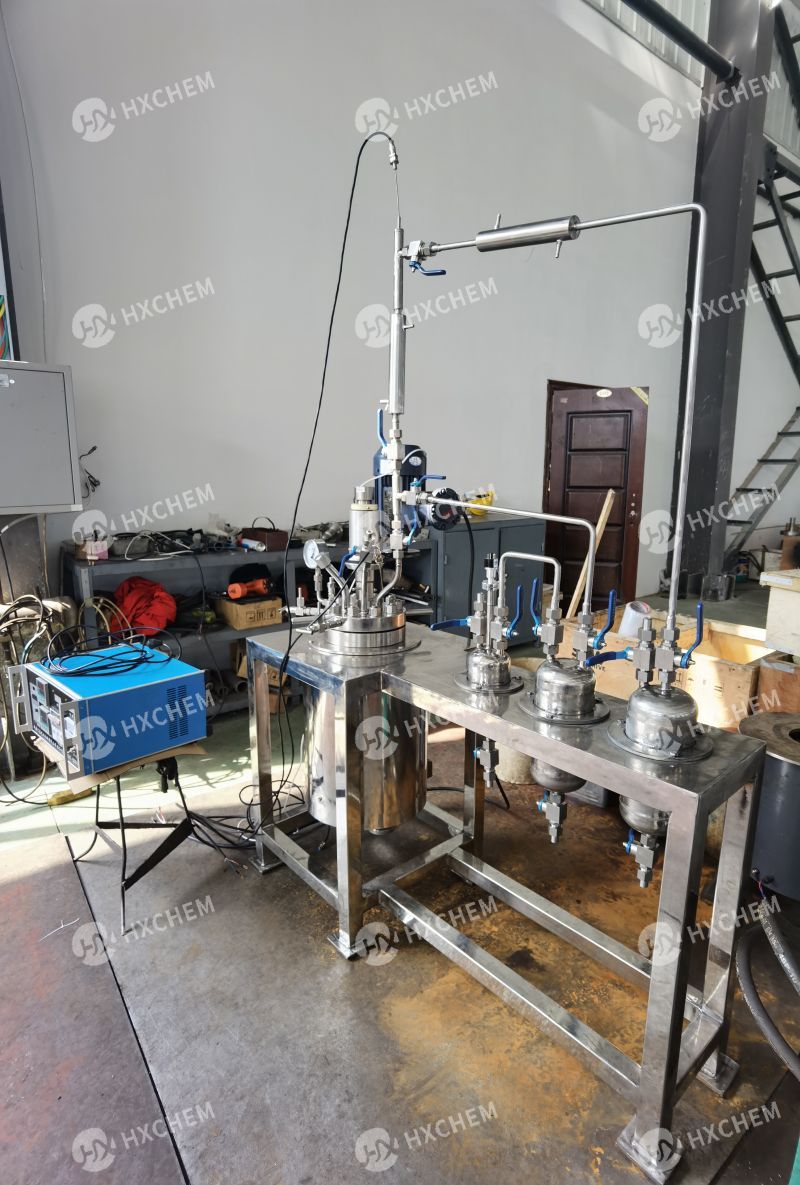

A HXCHEM kevert nyomású reaktor felszerelhető vákuumszivattyúval, gázkompresszorral, gázfokozó szivattyúval, külső kondenzátorral, vevővel, gázszabályozóval, ellennyomás szeleppel, vezérlőszeleppel. csővezeték, stb. Minden termék speciálisan az ügyfél igényei szerint tervezhető és gyártható.Laboratóriumi autoklávok 100 ml-től 50 literig.* Max nyomás: 300 bar; Max hőmérséklet akár 500 ℃Nyomástartomány 0,1-50 MPa, térfogattartomány 0,1-50 000 L. A reaktor anyaga lehet rozsdamentes acél, titán, nikkel, Hastelloy, Monel, Inconel és egyéb speciális anyagok stb.

A termék jellemzői

Rögzített, leszerelhető, csavaros szorítózár opcionális.

Nincs szivárgás mágneses csatolású keverő.

Karima/csavarok bilincs zárása opcionális.

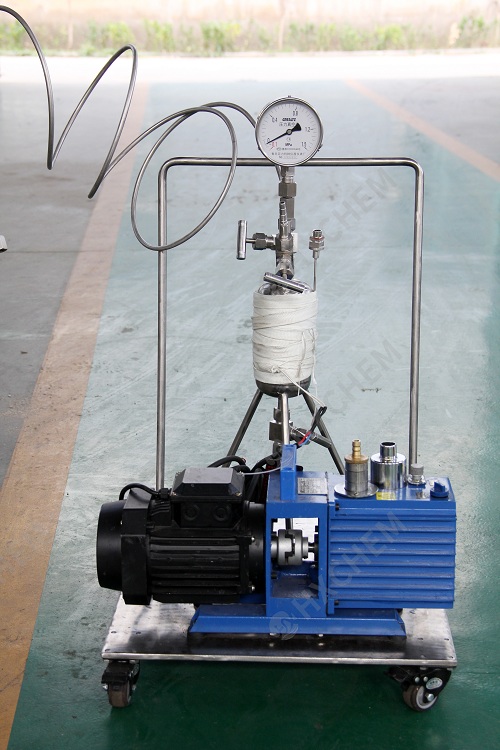

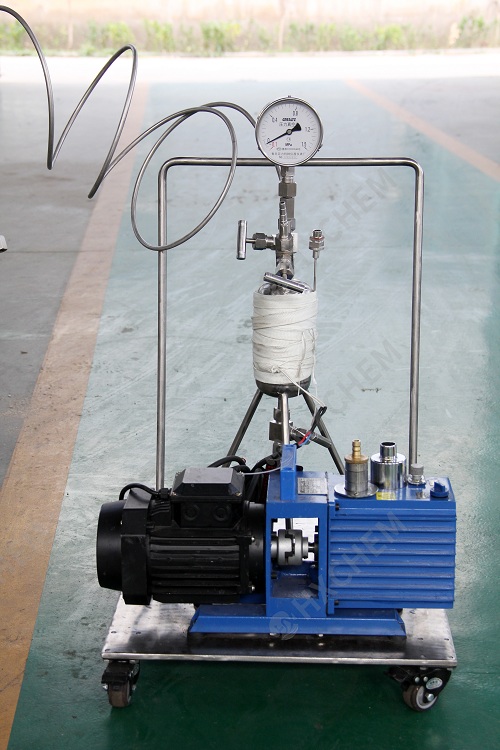

Vákuumszivattyú, gázáramlás kijelző, gázkompresszor, puffertartály, vákuummérő, légtelenítő szelep.

Külső kondenzátor, vevő, szabályozó szelep, reflux csővezeték stb.

Egyéb tartozékok: nagynyomású szivattyú, fix ágyas reaktor, ellennyomás szelep, csővezeték stb.

Szabványos specifikációk

GSH nyomásreaktor szabvány specifikációs táblázat.

| Model szám. | GSH-0.1 | GSH-0,25 | GSH-0,5 | GSH-1 | GSH-2 | GSH-5 |

| Névleges kapacitás | 100 ml | 250 ml | 500 ml | 1 liter | 2 liter | 5 liter |

| Max üzemi nyomás | Normál 100 bar; Max nyomás akár 350 bar | |||||

| Üzemhőmérséklet | Normál 350°C;Akár 500°C | |||||

| Keverési sebesség | 0-1500 ford./perc | |||||

| Motor erő | 150W | 150W | 150W | 0,2 kW | 0,2 kW | 0,6 kW |

| Fűtési teljesítmény | 1 kW | 1 kW | 1 kW | 2KW | 2KW | 4KW |

| Bezárás | Karimás csavarok zárása/bilincszár | |||||

Emelés és süllyesztés (Választható) | A fedél felemelése, az edény rögzítve A fedél kézi emelése, az edény forgatása Hajóemelés és süllyesztés, hajóforgatás Kézikönyv; Elektromos hajtású; Pneumatikus; Hidraulikus (hajtott módszer) | |||||

| Anyag | SS304, SS316 vagy más ötvözetek (titán, hastelloy, inconel, nikkel stb.) | |||||

| Fűtési módszer | Standard elektromos fűtés (köpenyfűtés, távoli infravörös fűtés opcionális) | |||||

| Hűtés | Belső spiráltekercsek(opcionális) | |||||

| Töltési mód | Felfelé nyomás nyomással vagy ürítés alsó szeleppel | |||||

| Keverős típus | Légcsavar, lapát típusú, turbina, horgony típusú, gázindukciós, spirál típusú stb. | |||||

| Kezelőpanel | Hőmérséklet kijelzés és vezérlés, pontosság 1℃, keverési sebesség kijelzés és szabályozás Érintőképernyős programvezérlés (opcionális) | |||||

| Szabványos szerelvények | Nyomásmérő, hőelem, központi keverőnyílás Folyadék bemenet/mintavételi nyílás tűszeleppel és merítőcsővel és gázbemenet tűszeleppel Biztonsági szakítótárcsa: Belső hűtés Tekercs (opcionális); Szilárd etetési pluszg (nem kötelező) | |||||